What’s the difference between chemical tempered glass and physical tempered glass?

SHENZHEN JIMY GLASS CO., LTD.

Original

2017-03-25 09:28:10

About chemical tempered glass

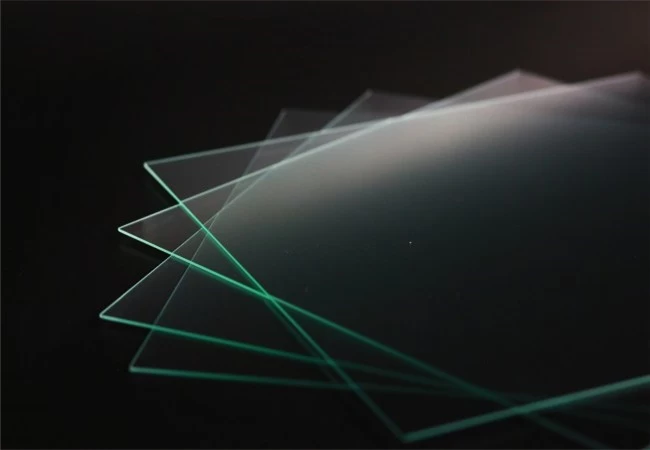

Chemical tempered glass also call chemical toughened glass, it’s formed the surface compressive stress of the glass by ion exchange. The theory of the ion exchange is that the smaller ion in the surface of the glass is exchanged with a larger radius in about 400LC alkali salt solution. For example, the lithium ions is exchanged with the sodium ions of the glass, sodium ions is exchange with the potassium ions. Taking the advantage of making surface compressive for the difference in the alkali ion volume. But it doesn’t effect more on the glass whose thickness is more than 5mm. The best thickness is 2-4mm glass, mostly we use is the termpered patterned glass for solor panel.

The characteristic of chemical tempered glass

1.The warpage wil never happy to chemical tempered glass as it’s not go through the high temperature.

2.The flatness surface is same as clear float glass and it performance in strength and temperature will become higher.

3.The disadvantage of resulting in stress relaxation as time pass.

What’s physical tempered glass?

Physical Tempered glass is make the ordinary annealed glass cut to size, and heated reach to softening point about 700 ℃, then suddenly cooling. Generally speaking, thickness of 5-6mm glass need to be heat 240 seconds under the high temperature of 700 ℃ and cooling about 150 seconds. While the thickness of 8-10mmm glass need to be heat 500 seconds under the high temperature of 700 ℃ and cooling about 300 seconds. In a word, the cooling time is depends on the thickness of the glass. After tempering, The glass surface forms a uniform compressive stress and internal tension is formed as well. All these resulting glass bending and impact resistance enhanced. It said that the strength is more than 4 times higher than the ordinary annealed glass. We can make the processed on the glass such as cut to size, edge polish, cutout etc, but all these must be done before tempered.

Physical tempered glass as safety glass which is widely used in building material field, such as shower door glass, partition wall glass, windows and doors glass etc. while chemical tempered glass is mostly for windows glass and roof glass of agricultural greenhouse or doors and windows glass of portable house, which is highly request for the temperature.