Why all the tempered glass need to be edging?

As one type of safety glass, the tempered glass is widely used around us, includes tempered glass doors, windows, balconies, shelves, bathroom enclosures, table tops, etc. Very often, clients tell us that they will use other materials like aluminum profiles to cover the tempered glass, so they don’t need the tempered glass with all around polished edges, but no matter how, we will do the tempered glass with polished edges, do you know why?

The main reason is putting the glass without edging into the tempering furnace, will damage the tempering furnace, and will influence the tempered glass quality, details as below:

1. If the glass without edging or fine grinding, in the process of heating and cooling, the defects of the edge of the glass are likely to cause "fried furnace" and "wind explosion" due to excessive stress or uneven stress, which will cause relatively serious tempering furnace damage;

2. If the glass is not edged before entering the furnace, there will be tiny glass slag particles on the glass sides. When the equipment is driven and oscillated, these tiny slag particles will fall on the roller table. Especially when it falls onto the ceramic roller table in the furnace, the pressing of the glass will adhere to the ceramic roller table at high temperature. And when the glass passes, it will lead to more serious pitting on the glass, which effects the glass quality.

And when this situation happen, we have to stop and cool the machine, and then thoroughly cleaning the ceramic roller. If frequent shutdown and cool the tempering furnace, it will not only increase our operating costs of the equipment, but also adversely affect the service life of the equipment.

3. When the glass without fine grinding is driven on the roller table, it will cause different degrees of damage to the surface of the roller table. In particular, damage to the ceramic roller table will be permanent and irreparable. Similarly, for shaped glass, cutting notches, drilling holes, etc., the processed part should also be edged after cold working, to ensure that there is no burst or crack.

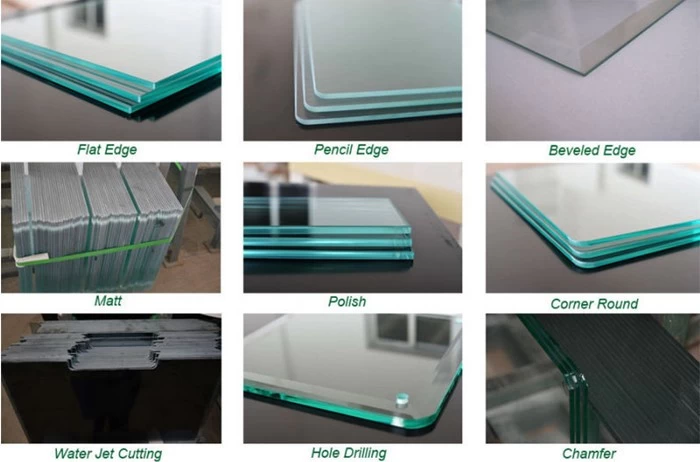

In conclusion, no matter you need or not, we will do the tempered glass with flat polished edges for you freely. We also could do other edges like bevelled edges, pencil edges, round edges, OGEE edges, different edges, the cost is different, welcome to contact us for more details.