How to improve the yield of tempered glass

SHENZHEN JIMY GLASS CO.,LTD.

ORIGINAL

2018-07-23 15:50:47

As we all known, tempered glass is human harmless safety glass, has widely application, we could see it anywhere, no matter on construction like windows, doors, balconies, partition walls, shower doors, etc., or on furniture like table tops, shelves, cabinet doors, etc., so there are more and more glass factories start producing the tempered glass, but seems that different factories has different cost for the tempered glass. Do you know how to improve the yield of tempered glass so that we could reduce the tempered glass price? Below some of our comments for your reference:

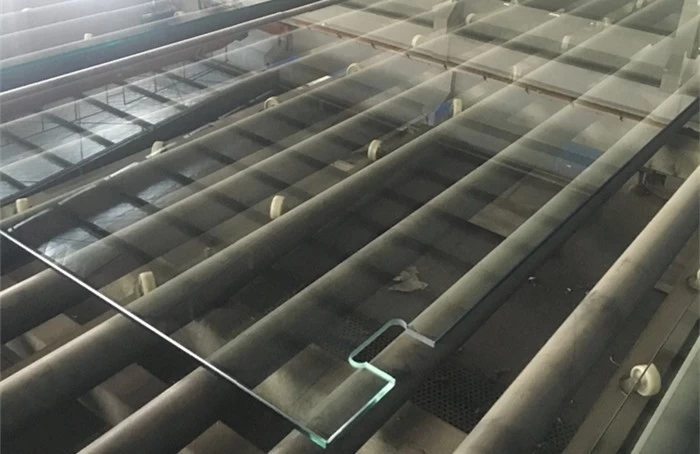

First, the glass must be edging before tempering

The quality of glass edging plays a decisive role in the yield of tempered glass. The effect of edging is more beautiful and is not easily broken during tempering, which could improve the yield of tempered glass.

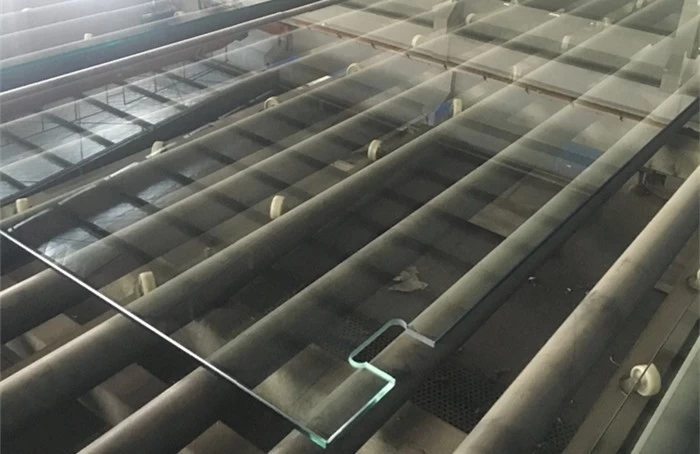

Second, adjust the process parameters of tempering

The tempering process parameters are including heating temperature, heating time, tempering cooling wind pressure time and tempering cooling time. The higher the tempering heating temperature, the shorter the heating time. A reasonable heating time needs to be selected after the temperature is determined. In general, the heating time per millimeter is about 40 seconds. However, it is necessary to increase the heating time by 10% when tempering the large glass panels, and increase the heating time by 10% when tempering the perforated holes and cut notches glass. So a flexible grasp of heating time and heating temperature is also the key to improving the yield of tempered glass.

Third, the importance of glass uniform heating

The glass is actually a cube, and the heating of the upper and lower sides is relatively slow. When tempering the big size glass, the middle of the glass is often heated very slowly. If want the large glass is heated evenly, need to set the furnace temperature curve, which the temperature in the middle higher than the set temperature by 10 degrees, and the temperature of the side is lower than the set temperature by 10 degrees. In this way, the tempered glass come out will have a uniform degree of flatness and graininess.

Trust that different factories have different methods to improve the yield of tempered glass, so that make sure the glass quality come out is excellent, but with lower cost, if you have better ideas, welcome to share your ideas with us any time.

First, the glass must be edging before tempering

The quality of glass edging plays a decisive role in the yield of tempered glass. The effect of edging is more beautiful and is not easily broken during tempering, which could improve the yield of tempered glass.

Second, adjust the process parameters of tempering

The tempering process parameters are including heating temperature, heating time, tempering cooling wind pressure time and tempering cooling time. The higher the tempering heating temperature, the shorter the heating time. A reasonable heating time needs to be selected after the temperature is determined. In general, the heating time per millimeter is about 40 seconds. However, it is necessary to increase the heating time by 10% when tempering the large glass panels, and increase the heating time by 10% when tempering the perforated holes and cut notches glass. So a flexible grasp of heating time and heating temperature is also the key to improving the yield of tempered glass.

Third, the importance of glass uniform heating

The glass is actually a cube, and the heating of the upper and lower sides is relatively slow. When tempering the big size glass, the middle of the glass is often heated very slowly. If want the large glass is heated evenly, need to set the furnace temperature curve, which the temperature in the middle higher than the set temperature by 10 degrees, and the temperature of the side is lower than the set temperature by 10 degrees. In this way, the tempered glass come out will have a uniform degree of flatness and graininess.

Trust that different factories have different methods to improve the yield of tempered glass, so that make sure the glass quality come out is excellent, but with lower cost, if you have better ideas, welcome to share your ideas with us any time.