Why is laminated glass degummed?

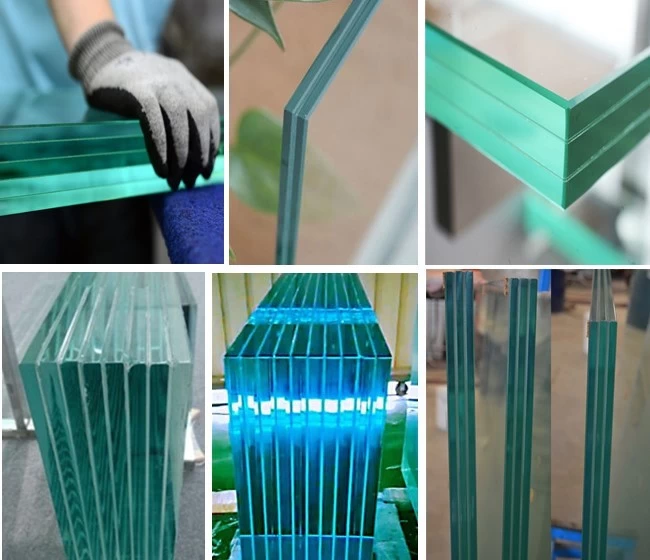

Degumming is the separation of the glass from the film after the laminated glass is completed or installed. The type of degumming has a ray shape, a worm or a finger shape, and a side disengagement.

The reason of degumming:

1.Film thinning: Due to the quality of raw materials or the way of loading and unloading before the autoclave, improper use of clips.

2.The glass is not well matched.

3.In the laminated glass, there are oil, detergent, water molecules, etc, which cause the glass surface to be dirty and the glass surface to have water, so that the film and the glass are not bonded firmly.

4.The inside of the autoclave is damp, causing moisture in the glass intermediate film.

5. Due to the storage and other reasons, the film with high moisture content is produced, and the moisture in the film cannot be excluded.

How to prevent the laminated glass from degumming?

1.Improve the loading method, keep the glass upright and have a certain gap between each other when entering the autoclave, and have reasonable support points; the sealing of the pressure roller should be good, and it should not be compensated by the large force clamp when it is not good, during the production process Strict pairing is required to ensure an increase in glass fit.

2.Due to the tempered deformation of tempered glass, the degree of fit is not good, and there are strict requirements on the flatness, bow shape and waveform index of the tempered glass to be laminated. The tempered laminated glass, which cannot be improved in waveform, is strictly matched to the production process to ensure uniform deformation; if necessary, the thickness of PVB can be increased to ensure that the laminated glass is not degummed.

3.The glazed glass should be cleaned and dried before it can be filmed to avoid excessive moisture in the interlayer. The cleanliness and temperature and humidity of the splicing chamber should be controlled within the required range to ensure that the splicing process is free from contamination.

4. If the edge is degummed and the water content of the PVB film is high, it can be determined that there is water in the autoclave. The source of the autoclave water should be checked to ensure the drying in the autoclave. Control the storage environment of the film, and measure the water content of the film before use to ensure that the moisture content of the PVB film is acceptable when the film is combined.