- Browse Categories

-

Tempered Glass

- Laminated Glass

- Insulated Glass

- Curved Glass

- Glass Application

- Elevator Glass

- Curtain Wall Glass

- Floor Glass

- Table Top Glass

- Roof Glass

- Photo Frame Glass

- Window and Door Glass

- Balustrade Glass

- Shower Door Glass

- Decorative Glass

- PDLC Smart Glass

- U-Glass

- Clear Float Glass

- Tinted Float Glass

- Reflective Glass

- Low Iron Glass

- Low E Glass

- Mirror Glass

- Aluminum Veneer

- Anti-reflective Glass

- Laminated Glass

- Certifications

-

- Subscribe

-

Get email updates on new products

- News

-

- How does a two way mirror work?

- Possible causes of defects in laminated glass and solutions

- The most comprehensive knowledge of the LOW-E glass

- Difference between heat-strengthened glass and fully tempered safety glass

- How to realize glass hot bending, cold bending or lamination bending?

- Difference between PVB laminated glass and SGP laminated glass

- Difference between PVB laminated glass and EVA laminated glass

- The packaging solutions for building glass

- What’s wired glass?

- The news of the Chinese shipping market and glass market

- Contact Us

-

SHENZHEN JIMY GLASS CO., LIMITED SHENKENG INDUSTRIAL ZONE, SHENFENG ROAD, LIUYUE, HENGGANG, SHENZHEN, CHINA TEL: 0086 755 28211334 / 0086 755 8934... Contact Now

High performance and CE standard acid etched frosted satin colored pvb tempered laminated glass for decorative effects

- Item: Frosted tempered laminated glass, satin ESG VSG, toughened laminated glass;

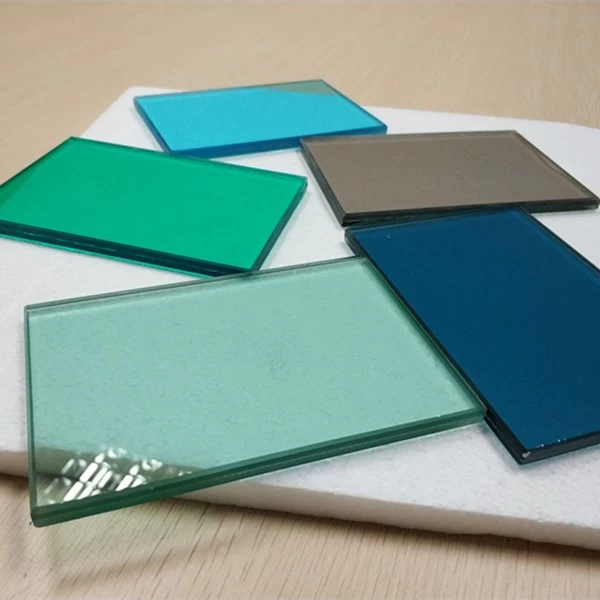

- PVB color: Red, yellow, blue, green, black, white, support customized requirements based on color pantone;

- Thickness: 6+6mm, 8+8mm, 10+10mm and other thickness combination;

- Size: flat shape maximum size reach 3300*8000mm, curved shape minimum radius reach 600mm;

- Processing works: holes drill, edges polish, irregular shape, all of this will based on drawing;

- Quality standard: according to ISO 9001, CCC, CE-EN14449, SGCC- Z97.1;

- Packaging: high performance safe export plywood crates with corks separate and plastic film fully covered;

- Delivery time: 20 working days after order confirmed.

High performance and CE standard acid etched frosted satin surface colored pvb tempered laminated glass for decorative effects

Satin surface processed color pvb tempered laminated glass, also called acid etched glass processed color pvb tempered laminated glass or frosted processed color pvb tempered laminated glass, which select good quality float glass at first, frosted processing, tempering, then laminating, make sure durable, good appearance in building projects.

How satin surface pvb tempered laminated glass production?

1.We will select high quality float glass as raw materials, cutting, edging, then ecid etched glass, make sure the surface texture uniform and flat, the tempering and laminating processing will be better and easier.

2.Use professional test instrument to inspect tempered glass pressure, and whether have Impurities in it, make sure its self explosion rate in less than industry standard

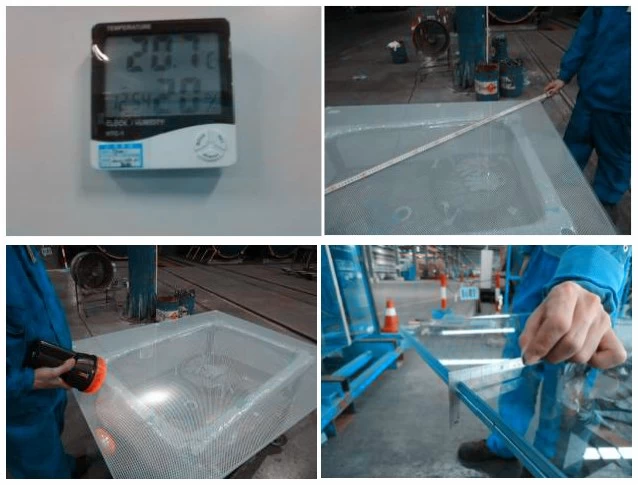

3.When laminated processing, make sure the temperature is 15-25 Celsius, humidity 20-28%, use ruler check the two layers of glass whether flush

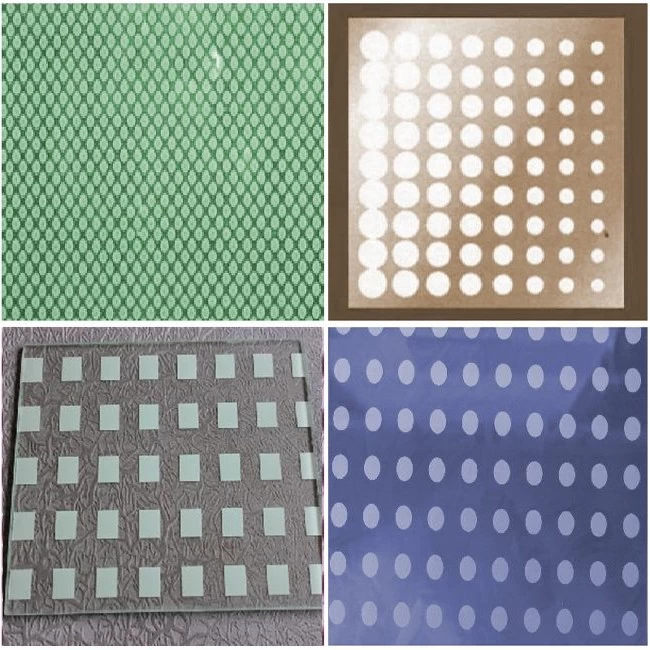

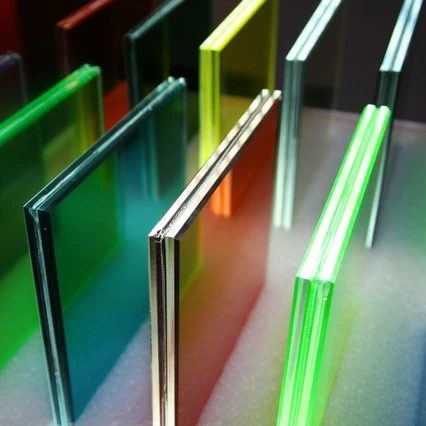

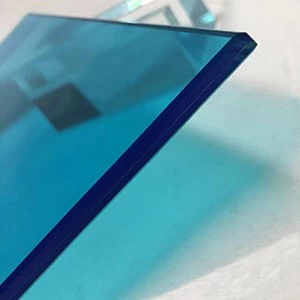

Some our finished frosted surface color pvb tempered laminated glass products photo share:

This kind of decorative glass is a good choice which widely use different building projects, makes building beautiful and modern.

Specification of Satin surface color pvb tempered laminated glass

| Available thickness | 6+6mm, 8+8mm, 10+10mm, 1/2, 5/8, 3/4 |

| Available size | Flat shape reach maximum 3300*8000mm, minimum radius of curved shape reach 600mm, size reach 2440*5500mm |

| Color choice | Red, yellow, blue, green, black, white, support customized based on color pantone |

| Features | Decorative, privacy, high safety, noise reduction, heat reduction |

| Delivery time | 15-20 working days when drawing and order confirm |

| Packages | Brand new high safety strong plywood crates, with corks separate glass, and outside fully conver plastic film |

Why choose us and our laminated glass products?

1) Select grade A float glass with no chips zero bubbles, zero scratches and perfect flat surface performance.

2) Our own advanced temper machine to guarantee our tempered laminated spider glass quality, with splendid temper stress uniformity, the self explosion rate reduce to 0.1%, or closed to 1/10000 even Zero when use low iron float glass tempered after heat soak test, and laminate machine will make sure edge alignment between laminates smaller than 2mm, 100% zero delaminate.

3) Much strict quality control according to ISO9001, make sure accurate size, thickness, and process works when delivery

4)Use brand new customized strong plywood crates with corks separate and plastic film fully covered outside to guarantee loading safety and avoid breaking when sea transportation.

5) Provide one stop service, like supply high quality glass fittings like one side 304 material stainless steel spider fittings, two side 304 material stainless steel spider fittings, four side 304 material stainless steel spider fittings for durable use and convenient installation.