- Browse Categories

-

Tempered Glass

- Laminated Glass

- Insulated Glass

- Curved Glass

- Glass Application

- Elevator Glass

- Curtain Wall Glass

- Floor Glass

- Table Top Glass

- Roof Glass

- Photo Frame Glass

- Window and Door Glass

- Balustrade Glass

- Shower Door Glass

- Decorative Glass

- PDLC Smart Glass

- U-Glass

- Clear Float Glass

- Tinted Float Glass

- Reflective Glass

- Low Iron Glass

- Low E Glass

- Mirror Glass

- Aluminum Veneer

- Anti-reflective Glass

- Laminated Glass

- Certifications

-

- Subscribe

-

Get email updates on new products

- News

-

- How is the glass made?

- How does a two way mirror work?

- Possible causes of defects in laminated glass and solutions

- The most comprehensive knowledge of the LOW-E glass

- Difference between heat-strengthened glass and fully tempered safety glass

- How to realize glass hot bending, cold bending or lamination bending?

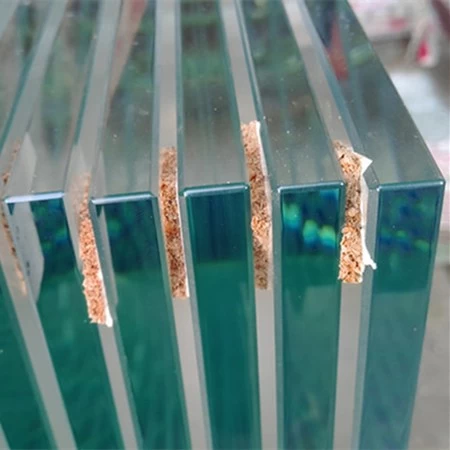

- Difference between PVB laminated glass and SGP laminated glass

- Difference between PVB laminated glass and EVA laminated glass

- What’s wired glass?

- The packaging solutions for building glass

- Contact Us

-

SHENZHEN JIMY GLASS CO., LIMITED SHENKENG INDUSTRIAL ZONE, SHENFENG ROAD, LIUYUE, HENGGANG, SHENZHEN, CHINA TEL: 0086 755 28211334 / 0086 755 8934... Contact Now

Wholesale prices heat soaked test heat strengthened fully tempered toughened glass manufacturer

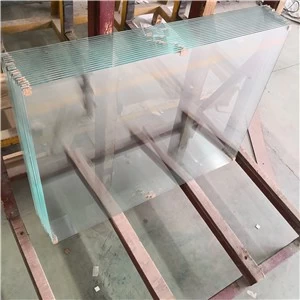

- Glass name: heat soaked tempered glass or name heat strengthened toughened glass or fully tempered glass

- Glass shape: flat heat soaked tested glass or curved heat soaked tested glass

- Glass color:French green heat soaked tested glass,Ford/dark blue heat soaked tested glass,Euro /dark grey heat soaked tested glass,bronze heat soaked tested glass, etc.

- Glass advantage: to reduce the risk of spontaneous tempered glass breakage.

- Within 10-15 working days production time after the order is confirmed

- Quality guarantee at least 10 years on normal used

China high quality heat-soaked toughened glass suppliers

What is heat soaked tempered glass ?

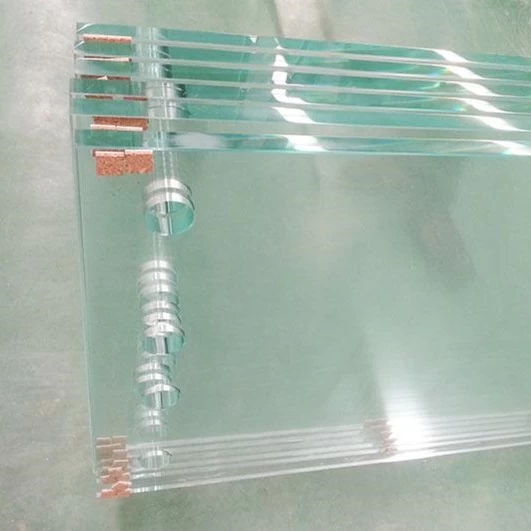

Heat strengthened treatment is also called "detonation". The heat soaking treatment is to heat the tempered glass to 290 °C ± 10 °C, and holding definite times, to urge the nickel sulfide can quickly complete the crystal phase transformation in the tempered glass, so that the tempered glass which may be self-explosive after use,to artificially broken in advance in the factory’s heat soaked furnace. Thereby reducing the self-explosion of the tempered glass in use after installation. This method generally uses hot air as a heating medium, which is called "Heat Soak Test" , referred to as HST, and is literally translated as heat strengthened treatment.

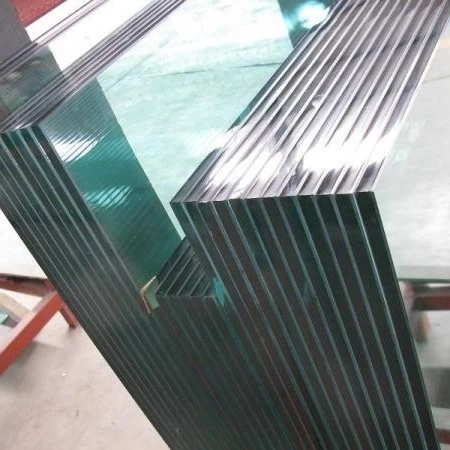

The specification of the heat soaked tested glass

| 1) Max size in 3300*12000mm, any customized size can be well done meet your requested. |

| 2) Glass color: except of clear, others available in ultra clear, green, blue, bronze, etc |

3) Glass type: clear heat soaked glass, low iron heat soaked tempered glass, tinted heat strengthened tempered glass, reflective heat soaked glass, acid etched heat soaked tempered glass, silk screen printed heat soaked toughened glass, heat soaked laminated glass, heat soaked insulated glass,etc |

| 4) Glass shape: flat heat soaked glass or curved heat soaked glass are available. |

| 5)Special processing, like flat polished edge, beveled edge, round safety corner, drill holes, …, all need to be finished before tempering. Holes finished by your CAD draft, logo printing also can be finished by AI file, etc. |

Advantage & Characteristics of Heat Strengthened Tempered (also called Fully Tempered) Glass:

Provides higher thermal and mechanical strength than annealed or heat-strengthened glass.

Approximately 4X the mechanical and thermal strength of annealed glass.

Tempered glass retains the normal properties of annealed glass including chemical resistance, hardness, expansion and deflection. It does not retain normal strength and breakage characteristics.

The break pattern for tempered glass is a pattern of small dices or particles. This is considered much safer than the often large sharp shards that may result from broken annealed or heat strengthened glass. Fully Tempered glass is often referred to as “Safety Glass” because of the break pattern.

May be prone to spontaneous breakage due to inclusions or tiny impurities in the glass such as nickel sulfide or if a treatment such as machining was applied to the edge post tempering causing the glass to weaken.

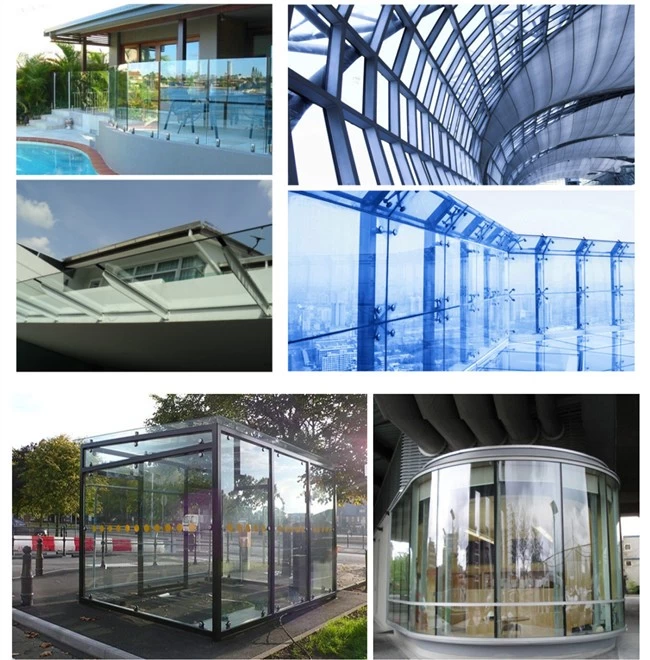

What is the function & application of this product?

The use of heat-soaked tempered glass is recommended where the risk of spontaneous breakage would cause difficulty, either from a replacement point of view, or where falling glass fragments may be unsuitable, such as roof or high level glazing, balustrades, screens and high level curtain walling.

Heat soak glass is appropriate where there is a risk of human impact. If breakage does occur, the breakage pattern is such that the resultant pieces of glass are relatively harmless and are unlikely to cause severe injury.

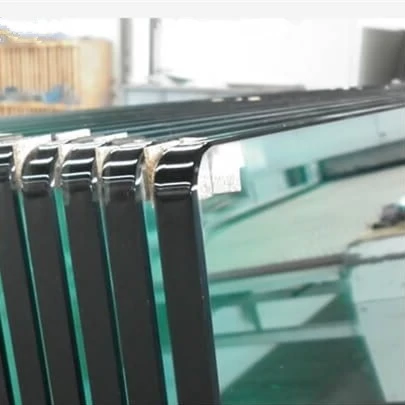

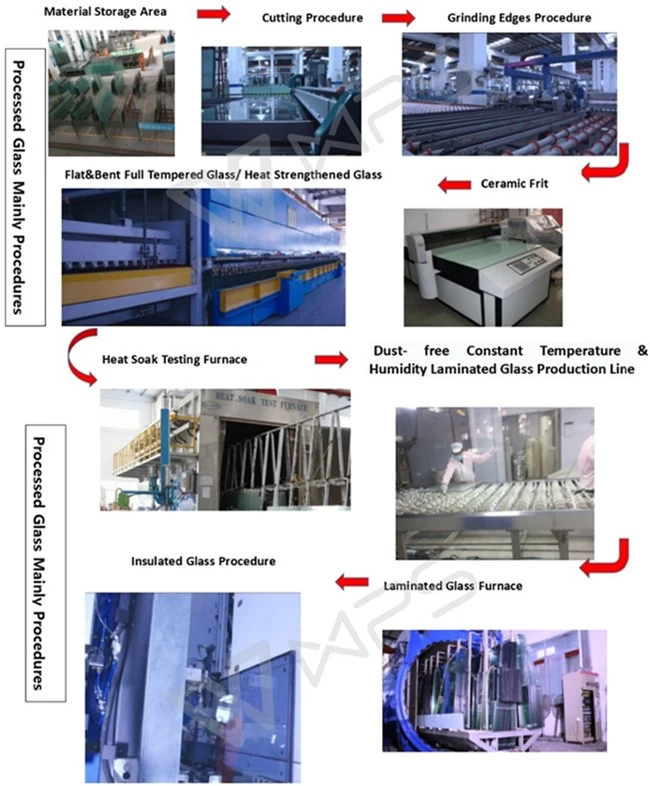

How to processed heat soaked tempered glass/ laminated glass/ insulated glass

The glass project of heat soaked tempered glass, heat soaked tempered laminated glass, heat soaked insulated glass,etc