- Browse Categories

-

Tempered Glass

- Laminated Glass

- Insulated Glass

- Curved Glass

- Glass Application

- Elevator Glass

- Curtain Wall Glass

- Floor Glass

- Table Top Glass

- Roof Glass

- Photo Frame Glass

- Window and Door Glass

- Balustrade Glass

- Shower Door Glass

- Decorative Glass

- PDLC Smart Glass

- U-Glass

- Clear Float Glass

- Tinted Float Glass

- Reflective Glass

- Low Iron Glass

- Low E Glass

- Mirror Glass

- Aluminum Veneer

- Anti-reflective Glass

- Laminated Glass

- Certifications

-

- Subscribe

-

Get email updates on new products

- News

-

- How is the glass made?

- How does a two way mirror work?

- Possible causes of defects in laminated glass and solutions

- The most comprehensive knowledge of the LOW-E glass

- Difference between heat-strengthened glass and fully tempered safety glass

- How to realize glass hot bending, cold bending or lamination bending?

- Difference between PVB laminated glass and SGP laminated glass

- Difference between PVB laminated glass and EVA laminated glass

- What’s wired glass?

- The packaging solutions for building glass

- Contact Us

-

SHENZHEN JIMY GLASS CO., LIMITED SHENKENG INDUSTRIAL ZONE, SHENFENG ROAD, LIUYUE, HENGGANG, SHENZHEN, CHINA TEL: 0086 755 28211334 / 0086 755 8934... Contact Now

664 clear tempered lamainated glass, 13.52mm safety toughened laminated glass manufacturers

- Made up with two pieces 6mm clear toughened glass

- Maximum size could reach to 3000*9000mm

- Cut to size, drilling holes, cutouts, polished edges, etc. must be done before tempering

- used as balustrade glass,storefront glass,outside canopy glass,etc.

- Production time within 10-15days after order is confirmed,if the product specification not change

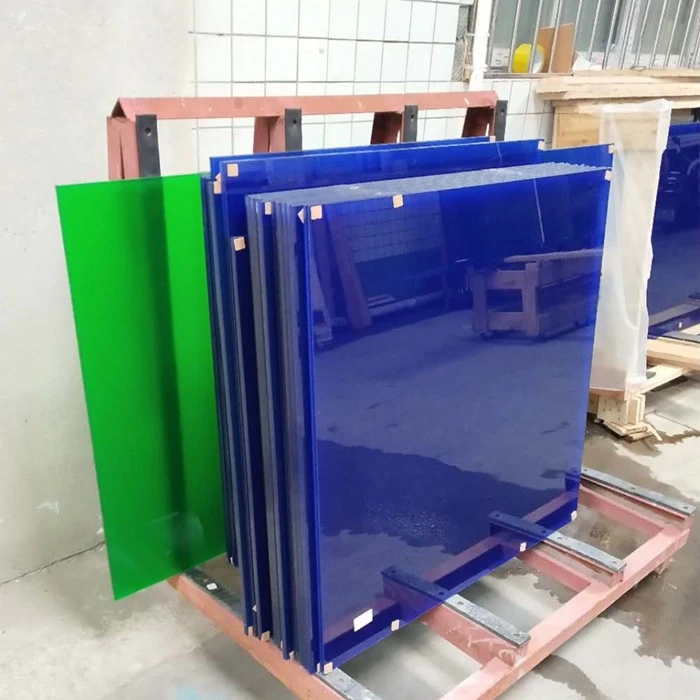

- All the glass packed in strong plywood crates with metal belt

13.52mm Clear Tempered Laminated Glass Manufacturers

About 13.52mm Ultra Clear Tempered Laminated Glass

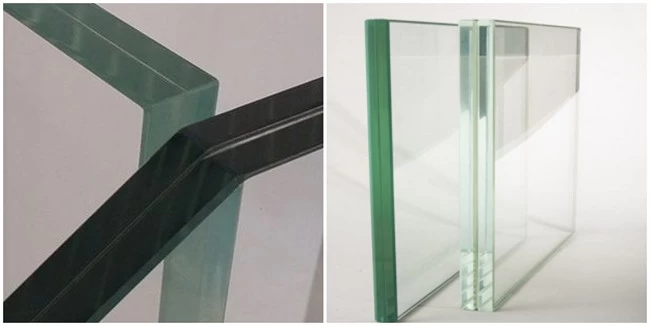

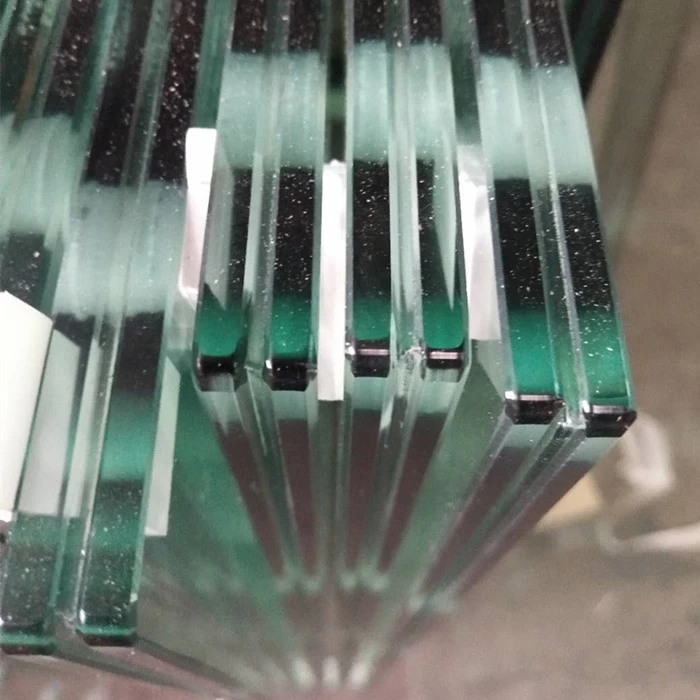

13.52mm Clear Tempered Laminated Glass is made up of two panels 6mm clear tempered glass permanently bonded together with 1.52mm PVB interlayer via a controlled, highly pressurized and industrial heating process. The lamination process results in the glass panels holding together in the event of breakage, reducing the risk of harm. Laminated Glass is classified as Grade A Safety Glass.

Clear Tempered Laminated Glass Characteristic

A. High Security

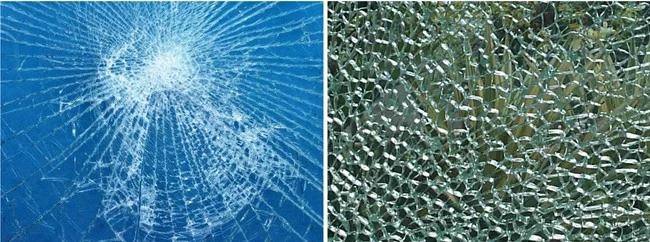

When laminated glass is attacked by outside force, it is hard to be penetrated because PVB film has strong tenacity and can absorb and weaken a mass of striking energy. Even if it's broken, the splinters will stick to the interlayer and not scatter.

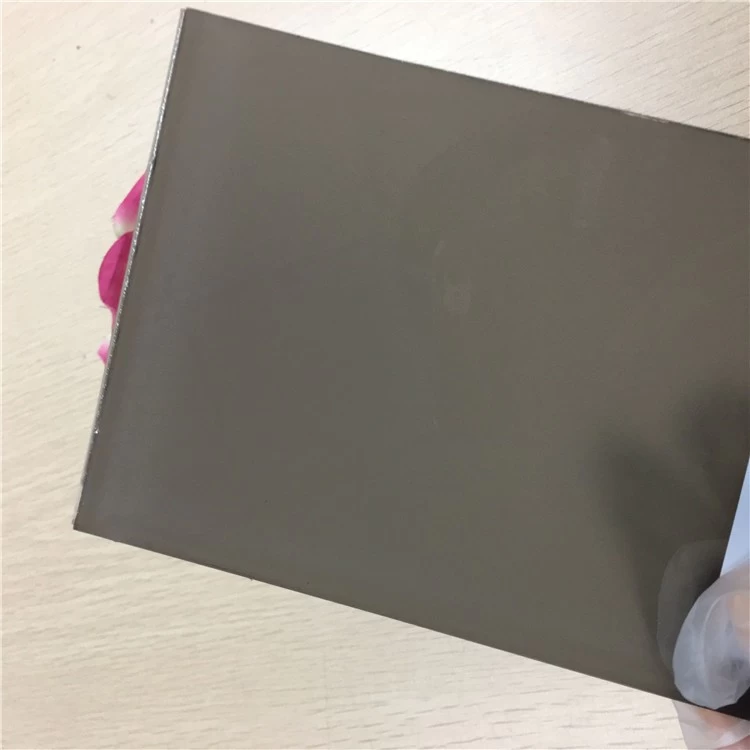

B. Super High Transparency

Clear laminated glass with highly transparency, and the neutral color making the glass perfect to use at where high visibility and clarity are required.

C. Create aesthetic sense to building

Clear laminated glass will beautify the buildings and harmonize their appearances with surrounding views which meet the demand of architects.

Tempered Laminated Glass Quality Standard

In accordance with GB15763.3, Chinese standard

In accordance with EN12543, European standard

In accordance with ANSIZ97.1, American standard

In accordance with AS/NZS2208, Australian standard

664 Clear Tempered Laminated Glass Specification

Size: max 3000*9000mm, mini 150*300mm

Composition: two pieces 6mm clear hardened glass with four layers clear PVB

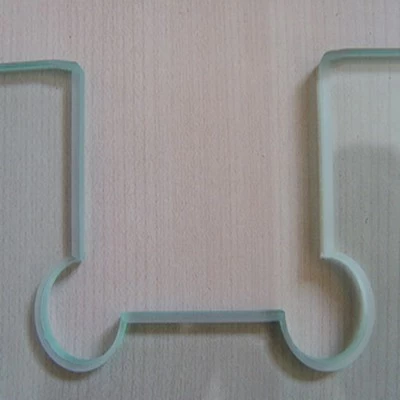

All the processing done on hardened laminated glass like cut to customized size, polished edges, cut notches, drill holes, etc. must be done before tempering.

13.52mm Clear Tempered Laminated Glass Application

• Shooping mall curtain wall glass, storefront glass, airport skylight glass

• Balustrade glass, long corridor glass, walkway glass, Partitions wall

• Many Others.

Processing Laminated Glass with Drilling Holes, Cutouts and Edge work