- Browse Categories

-

Tempered Glass

- Laminated Glass

- Insulated Glass

- Curved Glass

- Glass Application

- Elevator Glass

- Curtain Wall Glass

- Floor Glass

- Table Top Glass

- Roof Glass

- Photo Frame Glass

- Window and Door Glass

- Balustrade Glass

- Shower Door Glass

- Decorative Glass

- PDLC Smart Glass

- U-Glass

- Clear Float Glass

- Tinted Float Glass

- Reflective Glass

- Low Iron Glass

- Low E Glass

- Mirror Glass

- Aluminum Veneer

- Anti-reflective Glass

- Laminated Glass

- Certifications

-

- Subscribe

-

Get email updates on new products

- News

-

- How is the glass made?

- How does a two way mirror work?

- Possible causes of defects in laminated glass and solutions

- The most comprehensive knowledge of the LOW-E glass

- Difference between heat-strengthened glass and fully tempered safety glass

- How to realize glass hot bending, cold bending or lamination bending?

- Difference between PVB laminated glass and SGP laminated glass

- Difference between PVB laminated glass and EVA laminated glass

- What’s wired glass?

- The packaging solutions for building glass

- Contact Us

-

SHENZHEN JIMY GLASS CO., LIMITED SHENKENG INDUSTRIAL ZONE, SHENFENG ROAD, LIUYUE, HENGGANG, SHENZHEN, CHINA TEL: 0086 755 28211334 / 0086 755 8934... Contact Now

Colorless 10mm tempered glass manufactuer in China

- Glass type:tempered glass,safety glass,toughened glass,ESG glass.

- Thickness available: 4mm 5mm 6mm 8mm 9mm 10mm 12mm 15mm 19mm.

- Size:bespoke size (minmum 300mm x300mm, maximum 8000mm),cut to size by drawing.

- Color:clear, ultra clear, frosted, tinted color, printed color.

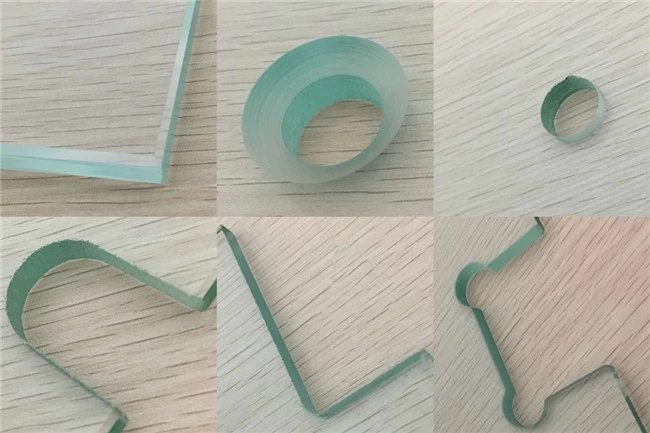

- Edge work: Flat polished edge, chamfer edge, beveled edge, waved edge, OGEE edge,etc.

- Delivery time: 7-15 days, urgent order can expedited processing service.

- Packing:Solid multi-layer wooden board crate export standard packing.

Colorless 10mm tempered glass manufactuer in China

Tempered glass is one of two kinds of safety glass regularly used in applications in which standard glass could pose a potential danger.(another safety glass is laminated glass).Tempered glass is four to five times stronger than standard glass and does not break into sharp shards when it fails.

Safety 10mm toughened glass is made by heating 10mm clear float glass(flat).It is manufactured through a process of extreme heating and rapid cooling, making it harder than normal glass. It results in the outer skins under powerful compressive stress and the interior with severe tensile stress. In consequence, the impact applied to the glass will be overcome by the compressive stress on the surfaces to assure safety of use. It is ideal for areas with high wind loads and areas where human contacts are an important consideration.

Tempered glass characteristics:

1. Strictly meet with building codes and safety requirements.

2. Strong enough to withstand high levels of thermal stress.

3. 4-5 times stronger than annealed glass of the same thickness.

4. Once breakage occurs, the glass disintegrates into small cubical fragments, which are relatively harmless to human body.

5. Sizes are produced as per customer request. once tempered, it can not be cut down.All work done must be done before tempering.

6. Can be printed with special logo and patterns with enamel silk screening.

7. Accept custom design,all kinds of shape,edge process and cutout.

Our tempered glass specification:

Size: Maximum 3000*8000mm, Minimum 150*300mm.

Tempered glass characteristics:

1. Strictly meet with building codes and safety requirements.

2. Strong enough to withstand high levels of thermal stress.

3. 4-5 times stronger than annealed glass of the same thickness.

4. Once breakage occurs, the glass disintegrates into small cubical fragments, which are relatively harmless to human body.

5. Sizes are produced as per customer request. once tempered, it can not be cut down.All work done must be done before tempering.

6. Can be printed with special logo and patterns with enamel silk screening.

7. Accept custom design,all kinds of shape,edge process and cutout.

Our tempered glass specification:

Size: Maximum 3000*8000mm, Minimum 150*300mm.

Thickness: 3mm 4mm 5mm 6mm 8mm 10mm 12mm 15mm 19mm.

Color: clear, ultra clear, green, blue, grey, bronze, etc.

Processing: All the processing like beveling, cutting, drilling, etc. must be done before tempering.

Where to used tempered glass?

1.Curtain wall.

2.Office partitions.

3.Sliding doors.

4.Shower door glass,bathroom partition.

5.Balustrades,fence, canopy, handrail.

6.Shop display windows, showcases, display shelves.

7.Exhibition hall.

8.Furniture, table-top.

9.Shopfronts in offices,houses,shop.

10.many other applications.

1.Curtain wall.

2.Office partitions.

3.Sliding doors.

4.Shower door glass,bathroom partition.

5.Balustrades,fence, canopy, handrail.

6.Shop display windows, showcases, display shelves.

7.Exhibition hall.

8.Furniture, table-top.

9.Shopfronts in offices,houses,shop.

10.many other applications.

Tempered glass quality:

1. Meet standards ISO,CCC,CE,certification.

2. High strength and puer clean surface. Select 40% of high quality clear glass for tempering.

3. Superior work on edge treatment,cutout,drilling holes.

4. Strong multi-layer wooden board crate package.

10mm clear tempered glass:

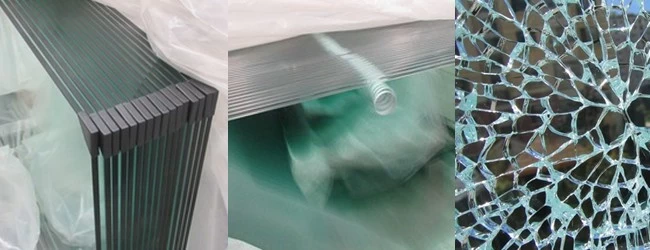

Tempered glass processing:

Safety tempered glasss application:

Tempered glass warehouse and machine.

Tempered glass strong packing and safety loading