- Browse Categories

-

Tempered Glass

- Laminated Glass

- Insulated Glass

- Curved Glass

- Glass Application

- Elevator Glass

- Curtain Wall Glass

- Floor Glass

- Table Top Glass

- Roof Glass

- Photo Frame Glass

- Window and Door Glass

- Balustrade Glass

- Shower Door Glass

- Decorative Glass

- PDLC Smart Glass

- U-Glass

- Clear Float Glass

- Tinted Float Glass

- Reflective Glass

- Low Iron Glass

- Low E Glass

- Mirror Glass

- Aluminum Veneer

- Anti-reflective Glass

- Laminated Glass

- Certifications

-

- Subscribe

-

Get email updates on new products

- News

-

- How is the glass made?

- How does a two way mirror work?

- Possible causes of defects in laminated glass and solutions

- The most comprehensive knowledge of the LOW-E glass

- Difference between heat-strengthened glass and fully tempered safety glass

- How to realize glass hot bending, cold bending or lamination bending?

- Difference between PVB laminated glass and SGP laminated glass

- Difference between PVB laminated glass and EVA laminated glass

- What’s wired glass?

- The packaging solutions for building glass

- Contact Us

-

SHENZHEN JIMY GLASS CO., LIMITED SHENKENG INDUSTRIAL ZONE, SHENFENG ROAD, LIUYUE, HENGGANG, SHENZHEN, CHINA TEL: 0086 755 28211334 / 0086 755 8934... Contact Now

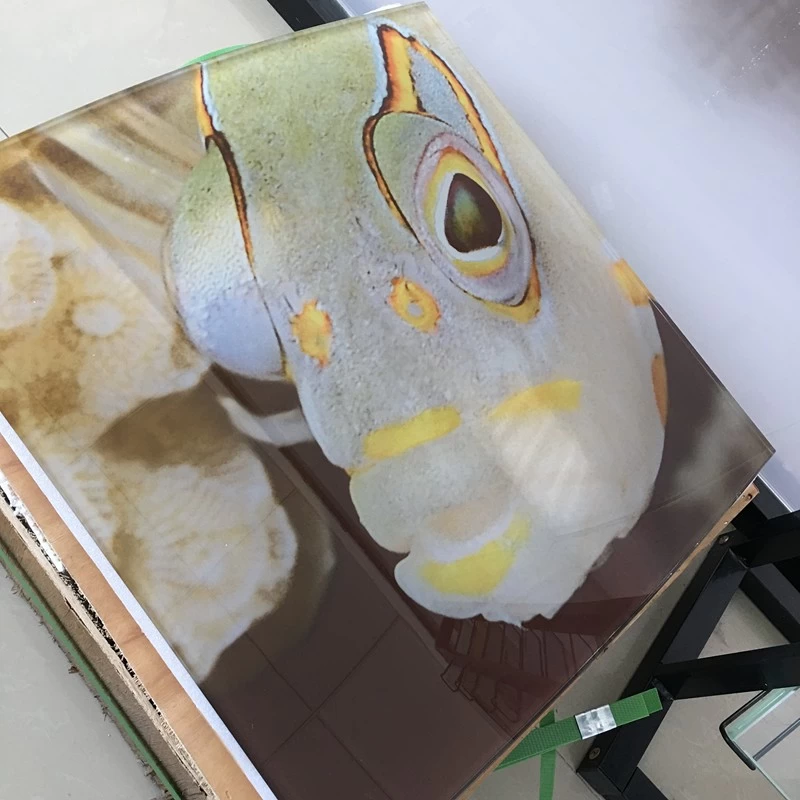

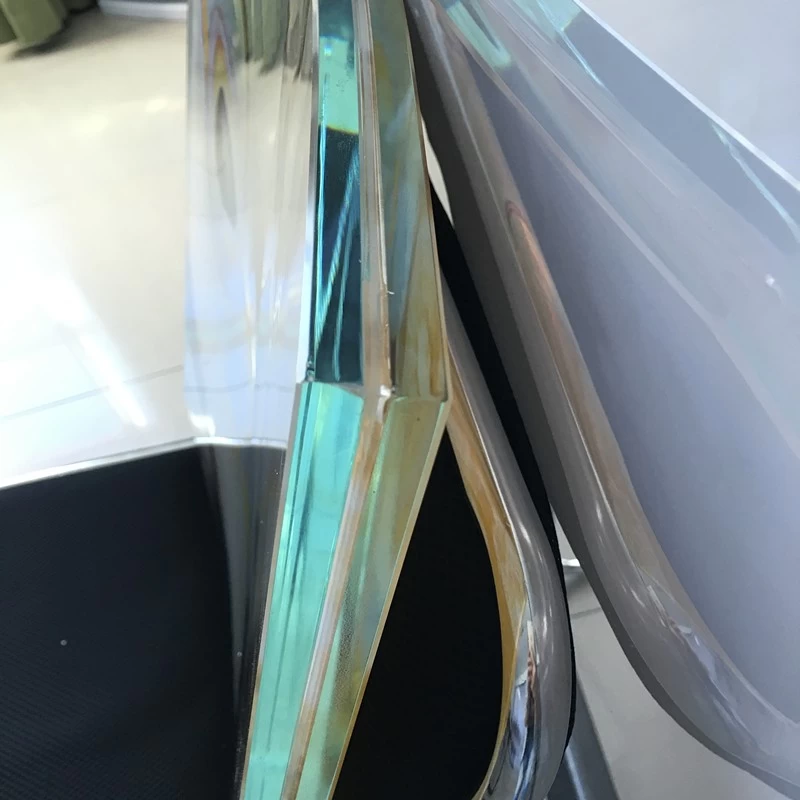

Image or photo or picture digital printing on glass structural curved laminated security decorative glass

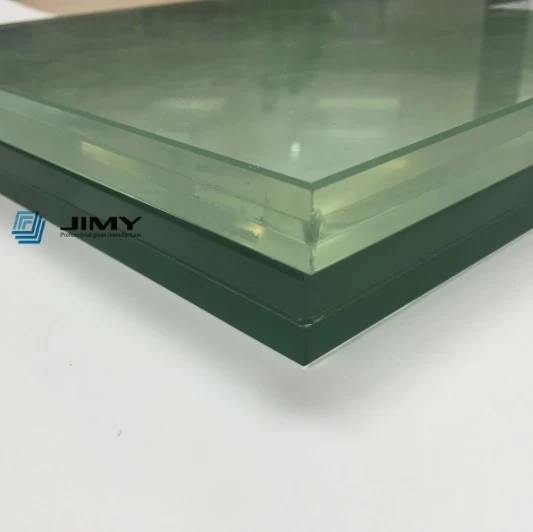

- Thickness: 4+4mm, 5+5mm, 6+6mm, 8+8mm, 10+10mm, 12+12mm, 15+15mm, 19+19mm, triple, four layers, etc. with the right amount of interlayer film according to the glass size and thickness

- Size: hot bent laminated glass could do any customized size, curved tempered laminated glass minimum radius 450mm, arc length max 1650mm, height max 2440mm, if want to reach bigger arc length like 2440mm, and bigger height like 3300mm, the radius should over 1000mm

- Design: we could print any image, picture, or photo on the glass, we also could print the required color in full surface, partial surface, or zebra line, any customized design

- Type: normal clear glass, ultra clear glass, color tinted glass, low-e glass, sandblasted glass, acid etched glass, etc.

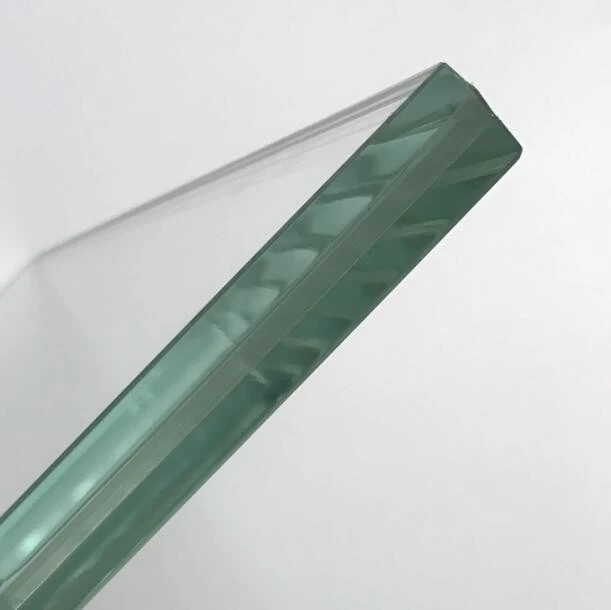

- Processing: polish edges, drill holes, cut shapes, cut notches, do safety corners, other customized requirement

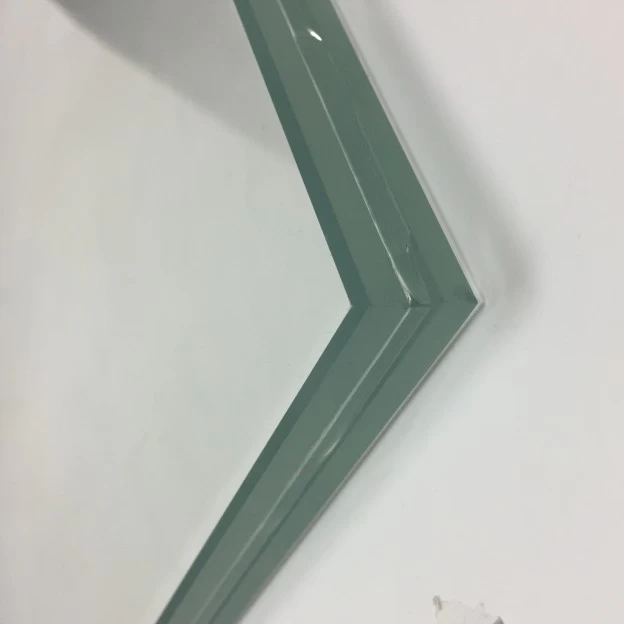

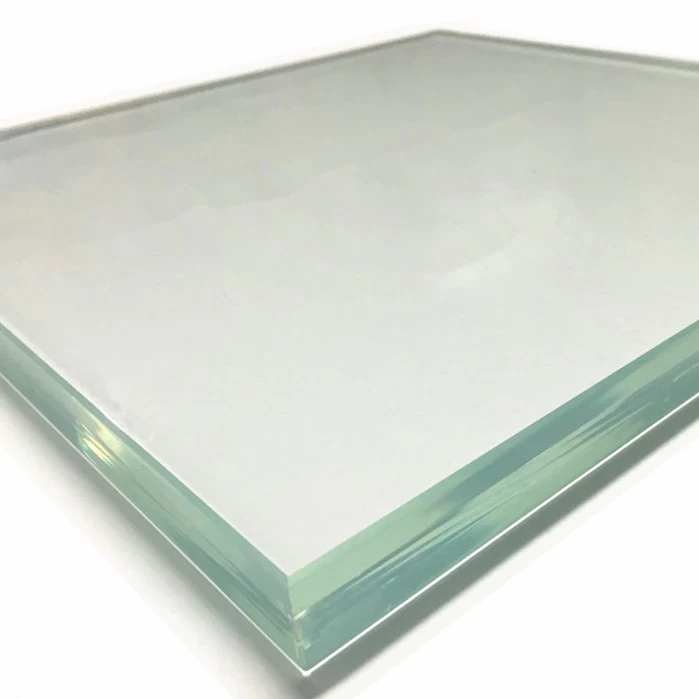

- Quality: no bubbles, no defects, super flat and smooth surface, 100% will not delaminate, very good alignment within 1mm, with European CE and American SGCC certificate

- Package: all the glass pack in export plywood crates as strong as possible

- Production time: 10-15 working days after order is confirmed

Digital printing curved laminated security decorative glass

Jimy Glass, is one of the most professional glass processing factories in China, advantage is producing different kinds of customized architectural curved glass, includes hot bent curved glass, and curved tempered glass, can be monolithic curved glass, also can be curved laminated glass.

Here we share with you one of our curved laminated glass-digital printing curved decorative laminated glass, which we could print the required image, picture or photo on the glass, to reach your desire decoration.

Product introduction

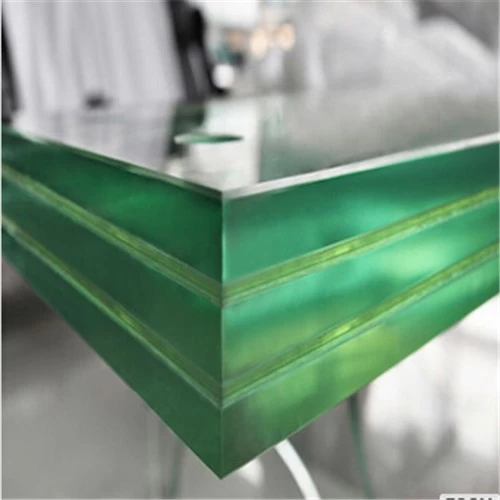

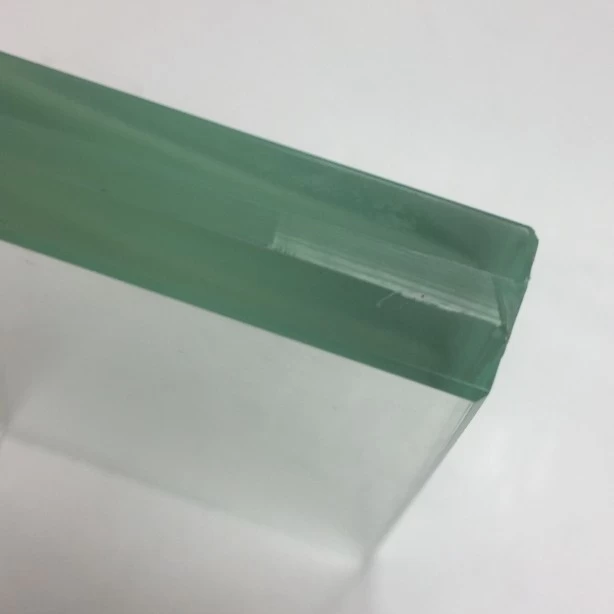

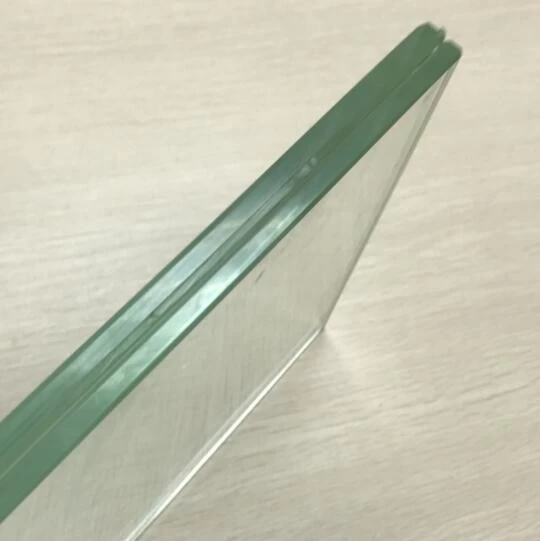

Digital printed curved decorative laminated glass, is bonded two or multiple layers of digital printed bent glass with interlayer film like PVB, EVA, SGP, with high temperature and high pressure, to make the glass stick with the film firmly. In this way, even the glass is broken by outside force, the glass will stick on the interlayer film, will not fall down to hurt human.

Regard to the curved glass, has the hot bending curved glass and curved tempered glass, the hot bending glass is heated to the softening temperature, and then rely on its own weight or external force to make the glass into a non-planar shape that matches the mold in a variety of specific shapes, using the annealing process to make the required curved glass, it is not safety glass, after broken, it will be in sharp pieces, easy to cut human, so should be careful. For the curved tempered glass, it is the glass under the tempering process heating the glass to over 620 degrees and then cool down rapidly by a strong wind jet, during the cooling, curving the glass at the same time, it is safety glass, 3-5 times stronger than normal annealed glass, after broken, it will be small obtuse particles, will not cut human.

So for safety and strong consideration, the digital printed curved tempered laminated glass is better than the digital printed hot bent laminated glass, but for the curved tempered laminated glass, it has the production limitation, for example, its minimum radius is 450mm, and want to reach this minimum radius, the glass should not too thick, and the max arc length not over 1650mm, the max height not over 2440mm, but for the hot bending digital printing laminated glass, don’t have the production limitation, it could do any radius with any sizes.

Production capacity

Thickness: 4+4mm, 5+5mm, 6+6mm, 8+8mm, 10+10mm, 12+12mm, 15+15mm, 19+19mm, triple, four layers, etc. with the right amount of interlayer film according to the glass size and thickness

Size: hot bent laminated glass could do any customized size, curved tempered laminated glass minimum radius 450mm, arc length max 1650mm, height max 2440mm, if want to reach bigger arc length like 2440mm, and bigger height like 3300mm, the radius should over 1000mm

Design: we could print any image, picture, or photo on the glass, we also could print the required color in full surface, partial surface, or zebra line, any customized design

Type: normal clear glass, ultra clear glass, color tinted glass, low-e glass, sandblasted glass, acid etched glass, etc.

Processing: polish edges, drill holes, cut shapes, cut notches, do safety corners, other customized requirement

Quality: no bubbles, no defects, super flat and smooth surface, 100% will not delaminate, very good alignment within 1mm, with European CE and American SGCC certificate

Package: all the glass pack in export plywood crates as strong as possible

Production time: 10-15 working days after order is confirmed

Product application

This is an artistic glass product, could widely use for decoration in different area, such as: glass partition walls, glass museum display screens, glass shopfronts, glass shower screens, etc.

Why buy glass from us?

1. We have professional sales and engineers, to understand exactly what you want

2. We have advanced machines and skillful rich experience workers, to produce the high quality glass products

3. We have strictly responsible QC, to make sure every piece glass come out from our factory is in very good condition

4. We have three production bases, to make sure the fast production time, generally, 10-15 days

5. We have strong export plywood crate packing, to make sure no damage during delivery

Any interest on our this product, or need more information, contact us any time.

Factory overview

Strict quality inspection

Glass safety packing and loading